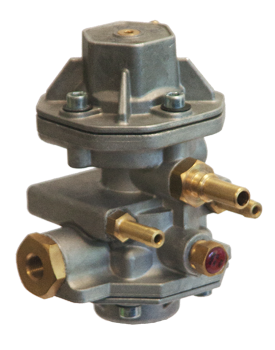

The MGH-CNG Pressure Regulators L2 and L3

The two-stage design provides cutting-edge performance in a compact package and the most stable output pressure available. An integrated high pressure filter casing, a shut-off valve and a fuel pressure sensor are included in our design and can be supplied with or without our integrated filter casing. This regulator (PR) is designed to exceed fleet and OEM standards of reliability and durability.

- MGH used the expertise of a leading German company in this field to develop the regulator.

- MGH used state-of-the-art software to simulate the functional behavior of this new development in both the short and the long term.

- MGH carried out a number of tests designed to guarantee the quality and working order of this new development in both the short and the long term.

- This regulator has passed all tests and requirements of ECE R 110 (2007 version).

- Supply of all materials and parts by best-qualified manufacturer.

Some of the tests which the MGH regulator passed successfully

- Durability test – 50.000 cycles (Test stand)

- Durability test of pressure regulator on vehicles (120.000 km)

- Pressure test for internal and external leakage

- Bursting pressure

- Corrosion test (salt spray & Ammonia)

- Ozone test

- Hysteresis tests

- Heat balance tests

- Material compatibility with CNG & engine coolant fluid

- Vibration resistance

This Regulator is designed to work in severe environmental conditions (muddy water, dusty air, heat, cold etc.).

Click here for:

Click here for:  Click here for:

Click here for: